For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

- +86-523-86183388

- +86-18036796868

- kiet@chinakiet.com

Single device capacity: 60-300 T

Synchronous sliding speed: 0-3m / min

Synchronous positioning accuracy: ± 3mm

Maximum number of connections: 99

Heavy load Lifting stroke: 200mm

Online connection mode: bus communication

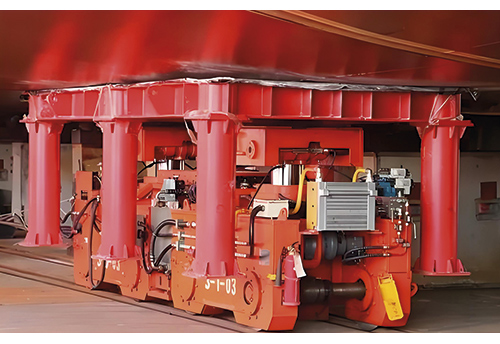

The carrying capacity of each equipment can be customized according to the actual load, and the modular design can meet the requirement of up to 99 devices for linkage synchronous control hydraulic. motor drive, with large driving capacity, small appearance and good waterproof performance.

High positioning accuracy, up to 3mm synchronous positioning accuracy, all parameters can be set in the general control room according to the needs of the working conditions.

Modern communication bus networking, electromechanical and hydraulic integration design, each bearing equipment is a complete hydraulic, mechanical and electrical control unit adopts heavy-duty roller support mode, small friction coefficient, high operation stability.

Real-time monitoring of displacement sensors and pressure sensors to ensure on-site construction.

The system has its own displacement out-of-tolerance and pressure out-of-tolerance alarm function to protect the safety of the site.

|

Load(t) |

60~300 |

|

Travel(mm) |

100~250 |

|

Work pressure(MPa) |

31.5 |

|

Suitable environment temperature(℃) |

-20~40 |

|

Driving mode |

Hydraulic motor |

|

Suitable track |

QU70/QU100 |

|

Whether a single trolley has independent walking |

Yes |

|

The trolley has a brake function |

Yes |

|

Number of wheels |

4 |

|

The trolley has an autonomous support function |

Yes, self-supporting structure |

|

The trolley has a rotation function |

Yes, manual assisted rotation is required |

|

|

|

| Gas storage tank transfer | ||

|

|

|

| Hull transfer | ||

| File Name | Format | Language | Download File |

|---|