For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

- +86-523-86183388

- +86-18918158399

- kiet@chinakiet.com

This system uses hydraulic driving, pressure and displacement closed-loop automatic control mode to realize multi-point control, widely used in replacement of highway bridge rubber bearings, overpass lifting, synchronous lifting of inland river bridge, equipment lifting and rectification etc.

System Composition and Main Principle

This system is composed of 1 high pressure pump station, control valve groups, hydraulic cylinders, stroke monitoring devices, pressure monitoring devices and 1 set of electrical control system.

Hydraulic pump station controls the flow by on-off valve, depending on regulating the switch frequency to change the flow which achieves the purpose of output flow can be regulated continuously. Accurate control on the synchronization of each hydraulic cylinder in lifting and load balancing in weighing process can be achieved by matching with proper electric control device, to compose pressure and displacement closed-loop control.

Technical Parameters

Displacement Synchronous Precision: ≦±0.5mm

Power Supply: AC380V/50Hz ( 3 Phase)

Max. Working Pressure: 700Bar

Control Mode: Pulse-Width-Modulation

Operating Interface: Human-computer interface

Alarm device: Alarm lamp

Supporting the use of various types of low height hydraulic cylinders, applied to synchronous lifting and replacement of highway bridge rubber bearings.

| Model | Points | Synchronous Precision | Motor Power | Voltage | Working Pressure | Flow | Oil Tank Capacity | Weight | Dimensions |

| (mm) | (KW) | (AC/V) | (MPa) | (L) | (L) | (kg) | (mm) | ||

| KET-SMTB-4 | 4-point synchronization | ≤±0.5 | 2.2 | 380 | 70 | 2 | 130 | 220 | 760x870x1210 |

| KET-SMTB-8 | 8-point synchronization | ≤±0.5 | 2.2 | 380 | 70 | 2 | 130 | 240 | 760x870x1210 |

| KET-SMTB-12 | 12-point synchronization | ≤±0.5 | 2.2 | 380 | 70 | 2 | 130 | 260 | 760x870x1210 |

| KET-SMTB-16 | 16-point synchronization | ≤±0.5 | 5.5 | 380 | 70 | 5 | 200 | 380 | 1100x960x1130 |

| KET-SMTB-24 | 24-point synchronization | ≤±0.5 | 5.5 | 380 | 70 | 5 | 200 | 432 | 1100x960x1130 |

|

|

|

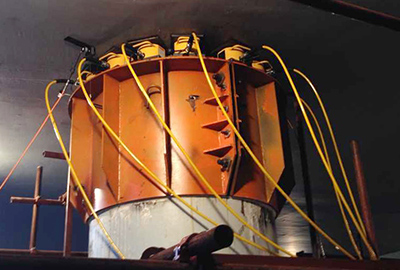

| Replacement of rubber bearings by 24 points synchronous lifting | Replacement of rubber bearings by synchronous lifting for highway bridges | Replacement of rubber bearings by synchronous lifting for bridges |

|

|

|

| Replacement of rubber bearings by synchronous lifting for viaduct | Replacement of rubber bearings by synchronous lifting for box girder structure with five span jacks | Replacement of rubber bearings for box girder basin-type support |

| File Name | Format | Language | Download File |

|---|