The ship’s sectional closing process is a common technology in the modern shipbuilding industry. The sectional assembly welding process can be used to build each section in parallel, thereby shortening the shipbuilding cycle and improving production efficiency.

In the past, the closing process was completed by a large crane, which has a small lifting tonnage and poor positioning accuracy. With the continuous improvement of manufacturing requirements, Canete has developed a fully automatic three-dimensional hydraulic adjustment equipment based on years of engineering construction experience. It can realize movement in three dimensions and six directions, so it is suitable for the shipbuilding section closed working condition. It is a modular design, which can be operated online by multiple sets of equipment to meet the tonnage requirements and positioning accuracy requirements on site.

At the beginning of this month, through repeated communication between Canete and the shipyard, the ship weighing 2224T was finally closed in place.

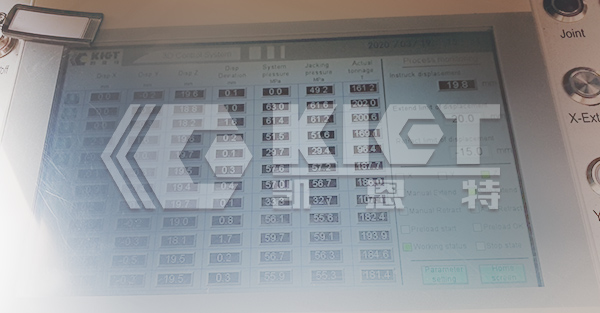

Canete KET-TZJ-250 fully automatic three-dimensional hydraulic adjustment equipment was used in the construction of this plan. The number of purchases was 12 units. The single equipment of this series had a Z-direction lifting force of 250T, a working stroke of 250mmand a X / Y-direction horizontal adjustment range 150mm.

Product advantages:

Improve the accuracy of ship segment positioning.

Improve shipyard production efficiency.

Reduce labor costs and safety hazards.

Modern product integrating mechanical, electrical and hydraulicwith stable and reliable equipment performance.

Modular design which can be assembled according to the actual situation on site to meet the requirements of different tonnages

Industrial network communication is used between devices to ensure the linkage of multiple devices and the reliability of data monitoring.

Post time: Apr-08-2020